With the rise of home baking, healthy eating, and restaurant-level culinary techniques around the world, baking tools are slowly transforming from “simple necessary tool items” into “quality and lifestyle” attributes. Whether for large supermarket chains, home decor chains, catering brands, or baking supply buyers, the question of whether to choose metal or ceramic baking pans in the long run is always one of the most frequently asked: Which is the better long-term purchase, metal or ceramic baking pans?

Metal baking pans are cheaper and heat up faster on the surface, while ceramic baking pans appear more refined and are often regarded as healthier and safer. But if you’re buying in bulk, business vs consumer, affecting cost structure, longevity, customer taste, and brand positioning, the decision is a whole different kettle of fish than ‘material differences.’ To spot the right baking pan for your dinner table, retail buyers must have a good understanding of the real differences in the cost, durability, and performance of baking pans from various materials.

This article focuses on the key point of metal vs. ceramic baking pans, to give a systematic analysis of the performance of these two kinds of baking pans in real baking. This article reviews both retail and wholesale to educate potential customers about the benefits and value associated with Ceramic Baking Pans in today’s market.

Cost Comparison: Purchase Price is Just the Beginning, Not the End

Considering the unit generation cost, metal baking pans are quite a bit cheaper than ceramic ones and that’s part of the reason why metal offerings tend to dominate the first-stage space at many retailers. But for grocery stores, chain retailers, or anyone purchasing in volume, the “real” cost of an item is never just its ex-factory price.

Metal baking pans are vulnerable to distortion, peeling off of coating, or rusting after long-term use, especially in cheap ones. The scrap rate is much higher after multiple uses in high temperatures. This requires more frequent stock replenishment for retailers, and more problems in after-sales service and complaints from consumers, both of which contribute to the rise of operating costs.

However, because of high-temperature firing, the structure of the Ceramic Baking Pan is stable, does not depend on any kind of chemical coating, and has less risk of breaking. In bulk orders, despite the slight increase in unit price, the one percent ceramic baking pan wins more in “cost per unit of use.” This is why more and more retailers have started to take notice of Wholesale Ceramic Baking Pans. In addition, ceramic baking trays give more space for premium pricing up in the value dimension space (design, added value, etc), rendering the development of mid-/high-quality product lines and the increase in unit margin easier in the mid-/high-end market.

Durability and Safety: The Real Differences Under Long-Term Use

Durability is not only a factor in the life cycle of a product but is also a direct influence on the user experience and the reputation of the brand. Metal baking pans are stable for the first time using; however, the coating tends to peel off under high temperatures or due to contact with acidic food or when the cleaning is improper. After the coating is scratched off, not only is the appearance affected, but consumers may even worry about food safety.

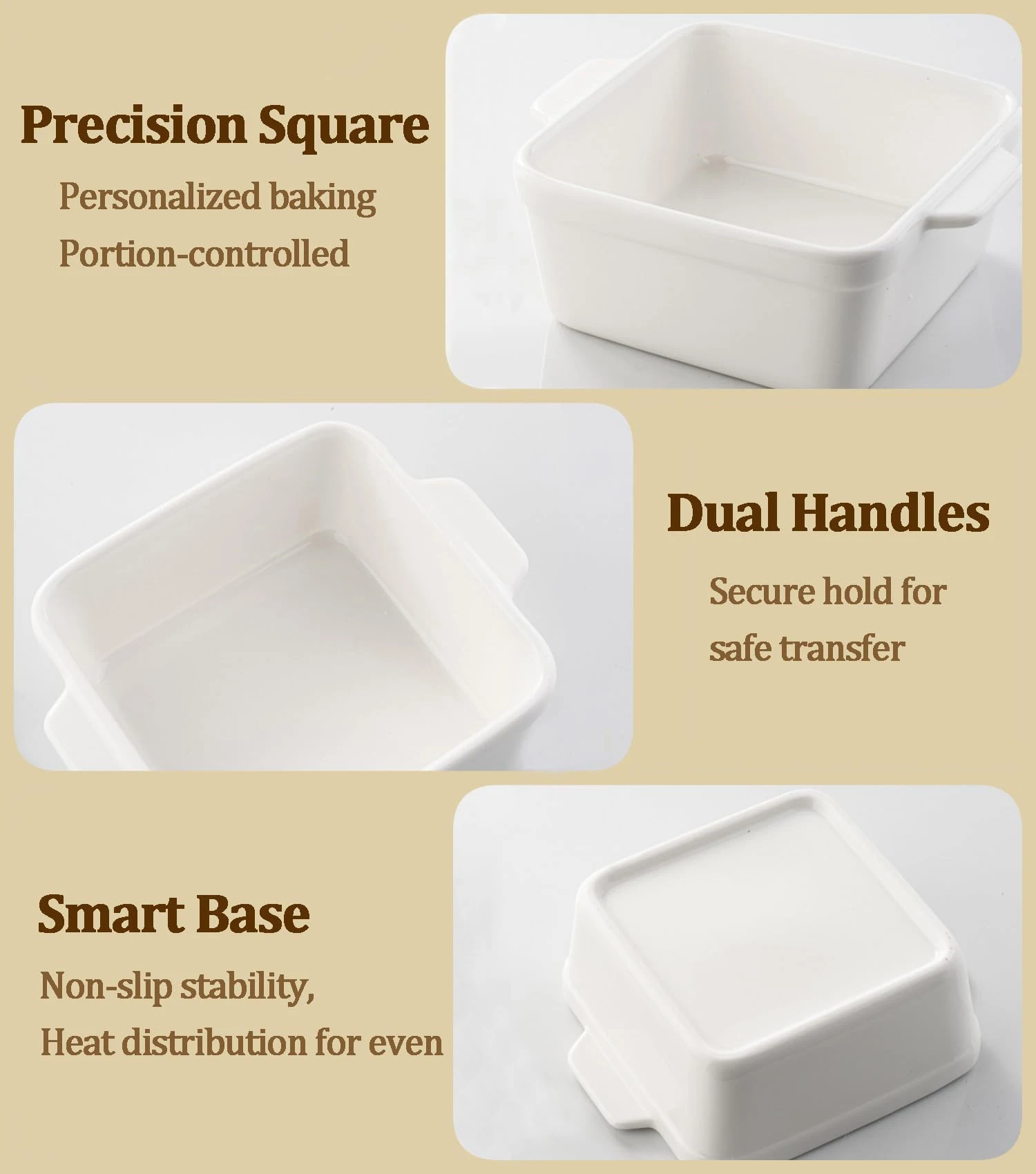

One of the best benefits of Ceramic Baking Pans is their natural properties. Premium ceramic baking pans usually feature glazes that are lead-free and cadmium-free, and are free from PFAS or any other questionable chemical coatings and are more likely to comply with the most rigorous international market standards when it comes to food safety. This is why more and more retailers want to cooperate with professional ceramic baking pans manufacturers in choosing products.

In terms of durability, moldes de cerámica are not easily deformed in normal use, the glaze is dense, the scratch resistance is good, and they long-term use in daily life and sales is more appropriate. This is particularly important for retailers looking for low return rates and high repurchase rates.

Baking Performance: Heating Method Determines Final Product Quality

In actual baking, even heating is often more important than “heating speed.” Metal baking pans conduct heat quickly but are also more prone to localized overheating, especially in home ovens. Novice consumers often struggle to precisely control the heat, easily resulting in burnt bottoms and uncooked interiors.

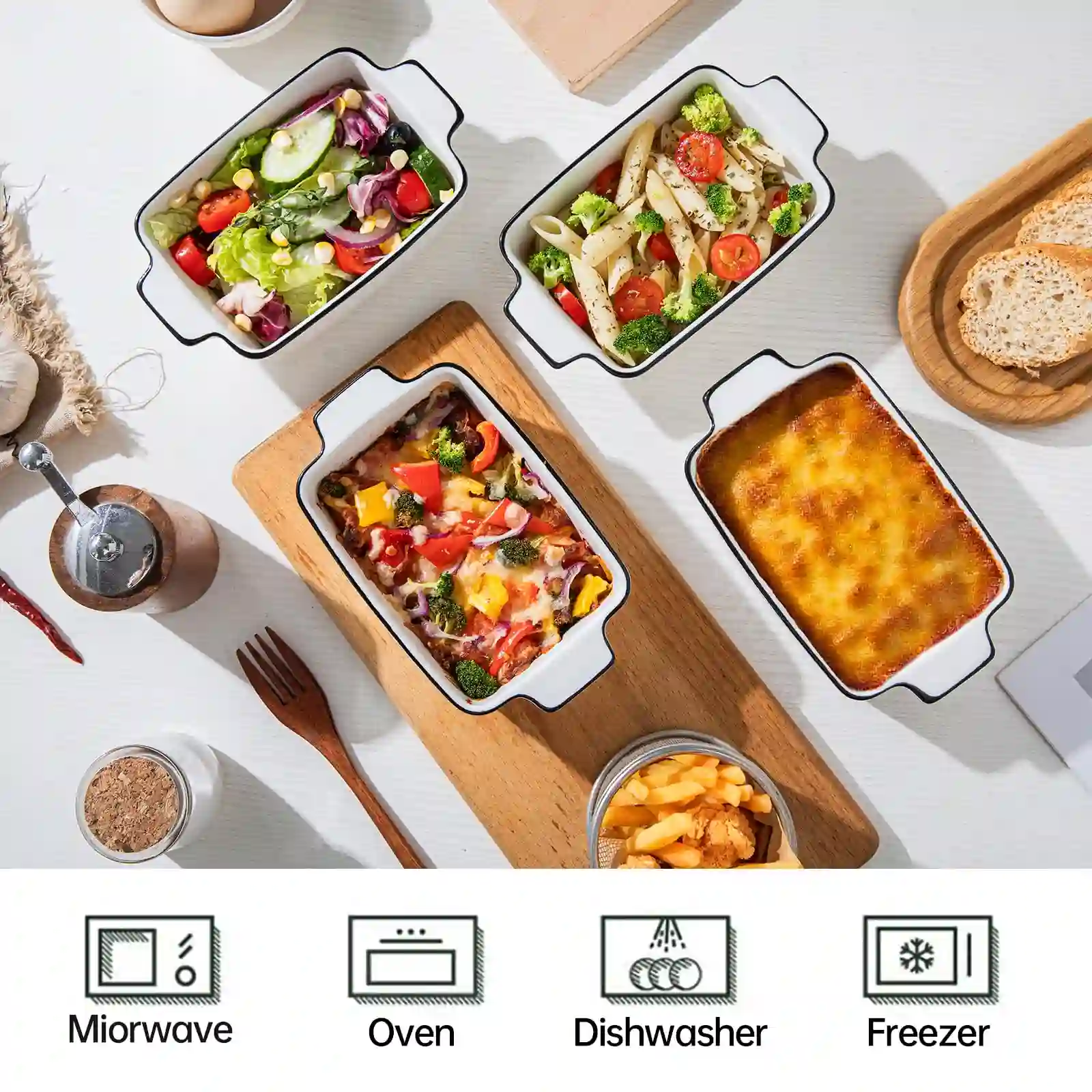

Ceramic Baking Pans have a relatively gentler heat conduction rate but stronger heat retention, maintaining a stable temperature distribution throughout the baking process. This characteristic makes ceramic baking pans ideal for making cakes, baked dishes, lasagna, and other foods requiring high temperature evenness.

In the retail market, an increasing number of consumers are using usability as a key criterion for repeat purchases. Consistent baking performance translates to higher user satisfaction, further enhancing the acceptance of Wholesale Ceramic Baking Pans in the end-market.

Appearance Design and Retail Display: Key Factors Influencing Consumer Decisions

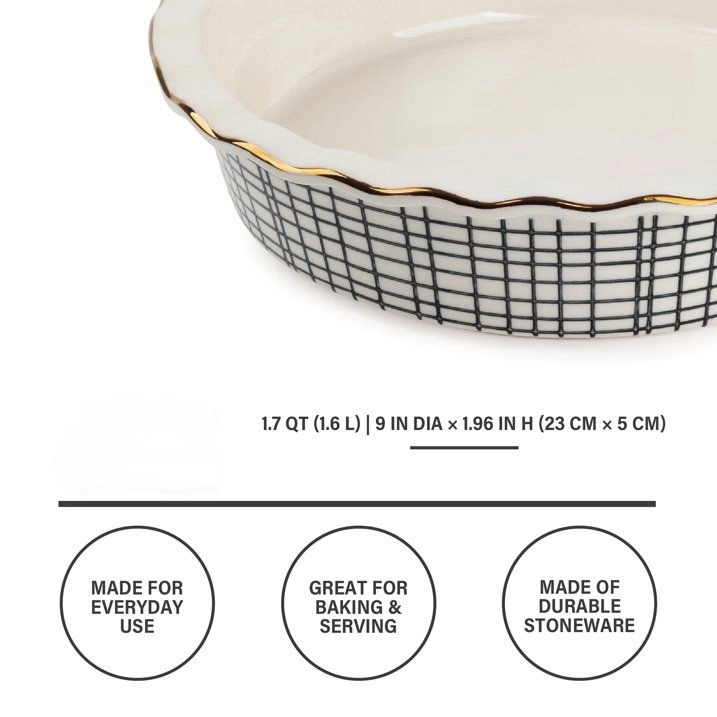

In supermarkets and home furnishing stores, consumers are typically attracted by their first impression. Metal baking pans are relatively functional in appearance, with limited design variations, making it difficult to create a strong visual difference on the shelf. Ceramic baking pans, on the other hand, can create rich product layers through color, glaze, shape, and texture.

Ceramic Baking Pans are naturally suited to being “ready to serve straight from the oven,” serving not only as baking tools but also as tableware and home décor. This multi-scenario use makes them easier for consumers to understand and accept in the retail sector.

For retail buyers, collaborating with Ceramic Baking Pans Manufacturers who possess design capabilities allows for customization of colors, sizes, and set combinations, further enhancing brand differentiation and strengthening shelf competitiveness.

Wholesale vs. Customization Perspective: Why Retailers Prefer Ceramic Baking Pans

At the wholesale procurement level, stable supply capacity, clear quality standards, and flexible customization services are equally important. Compared to more standardized metal products, Wholesale Ceramic Baking Pans offer greater flexibility in OEM/ODM.

Retailers can customize exclusive glazes, packaging designs, and product combinations based on target market demands, thus creating unique SKUs and avoiding homogeneous competition. Simultaneously, ceramic products are more easily associated with consumer trends such as “health, environmental protection, and quality living,” helping to enhance the overall brand image.

For retailers looking to establish a long-term presence in the baking utensil category, choosing a professional and reliable Ceramic Baking Pans Manufacturer is not just a procurement decision, but the beginning of a long-term strategic partnership.

Conclusion: A Rational Choice from Short-Term Costs to Long-Term Value

Metal and ceramic baking pans each have their applicable scenarios, but current retail market trends indicate that consumers’ focus on health, safety, and aesthetics is continuously increasing. Metal baking pans, relying solely on low-price competition, are no longer sufficient to meet the demands of the mid-to-high-end market.

Considering overall cost, durability, baking performance, and retail performance, Ceramic Baking Pans demonstrate a clear advantage in long-term value. Especially in wholesale and retail channels, Wholesale Ceramic Baking Pans not only help improve product mix but also bring higher added value and customer loyalty to the brand.

Acerca de Jinhua Ceramics

Cerámica Jinhua, established in 1990, is a professional Fabricante de cerámica diaria integrating R&D, production, sales, and service. We specialize in the manufacturing and wholesale of ceramic tableware, ceramic baking dishes, ceramic candle containers, and ceramic bathroom sets. As an experienced ceramic baking pans manufacturer, we provide global customers with stable and reliable wholesale ceramic baking pans and comprehensive Servicios de personalización OEM/ODM.

Cerámica Jinhua has obtained multiple international certifications, including BSCI, ISO9001, ISO14001, and ISO45001. With its excellent customer service and highly competitive prices, it has earned the long-term trust of numerous retailers and brand clients. If you are looking for a reliable ceramic baking pan partner, Jinhua Ceramics is the ideal choice.