في عملية تفصيل منتجات السيراميك، تُعد عينات السيراميك حلقة وصل لا غنى عنها في ضمان الجودة وتنفيذ تصميم المنتج. بالنسبة للعملاء الذين يحتاجون إلى مشتريات بالجملة أو تخصيص العلامة التجارية، فإن العينات ليست مجرد عناصر للعرض بل هي “مخطط” للإنتاج بكميات كبيرة في المستقبل.

Aمُصنِّع وتاجر جملة يتمتع بخبرة في مجال السيراميك للاستخدام اليومي، جينهوا يعرف مدى أهمية العينات ويقوم بإجراء منهجية احترافية ومنهجية عملية أخذ عينات السيراميك لأنواع مختلفة من المنتجات, من أدوات المائدة وصواني الخبز إلى أطقم الحمام وأوعية الشموع، بطريقة تسمح لكل منتج أن يعكس مفهوم العلامة التجارية للعميل بشكل مثالي.

ما هو أخذ العينات الخزفية؟ لماذا هو أمر بالغ الأهمية؟

ببساطة، أخذ العينات الخزفية هي مرحلة تأكيد العينة قبل إنتاج منتجات السيراميك المخصصة.

في هذه العملية، تقوم الشركة المصنعة بإنشاء عينات بناءً على متطلبات العميل من حيث التصميم واللون والحجم والشعار لتقييمها. تكمن أهميتها في ثلاثة جوانب:

- التحقق من جدوى التصميم: التأكد مما إذا كان شكل المنتج والتزجيج والملمس يلبي التوقعات من خلال العينات.

- ضمان جودة الإنتاج الضخم: ويضمن التأكيد في مرحلة العينة الاتساق بين طلبية السائبة والعينة، وتجنب أخطاء الدُفعات.

- جسر للتواصل مع العلامة التجارية: تُعد العينات الوسيلة الأكثر مباشرة للتواصل بين العملاء والمصنع، مما يتيح تكاملاً أكثر كفاءة بين التصميم والإنتاج.

في إنتاج جينهوا نظام أخذ عينات السيراميك هو عملية موحدة لكل مشروع. سواءً كان العملاء يحتاجون إلى أدوات مائدة سيراميك أو صواني خبز أو أواني شموع أو أطقم حمامات، فإن اختبار العينات يضمن تقديم المنتج النهائي بشكل مثالي.

عملية عينة السيراميك من جينهوا: من التصميم إلى النموذج الأولي

- التواصل مع احتياجات العميل

قبل بدء الإنتاج، فإن فريق تصميم جينهوا سيناقشون التفاصيل مع العملاء حول متطلبات المنتج، بدءًا من الشكل والحجم إلى الاستخدام واللون، بما في ذلك حتى التغليف. على سبيل المثال، تركز أطقم أدوات المائدة بشكل أكبر على التناغم الجمالي، بينما يتم التركيز على مقاومة الحرارة في صواني الخبز الخزفية.

نحن نقدم المشورة الاحترافية من خلال اختيار التزجيج المناسب وطرق الطباعة وخيارات تخصيص الشعار، وفهم وضع العميل وأهداف السوق.

- تأكيد التصميم وتخطيط النموذج الأولي

بعد التأكد من مخطط التصميم, جينهوا ستضع خطة نموذجية بناءً على نوع المنتج.

تتراوح الدورة العامة لأخذ عينات السيراميك من 7 إلى 15 يومًا، ولكنها تختلف بناءً على تفاصيل التخصيص. في المشاريع التي تنطوي على قالب جديد، مثل صواني الخبز ذات الأشكال الخاصة أو برطمانات الشموع المعطرة، سنبدأ في عملية صنع القالب حسب الطلب لضمان دقة الشكل.

- التشكيل والحرق على البيسك

يتم تشكيل الصلصال خلال مرحلة صنع العينة عن طريق الكبس أو الصب الانزلاقي ثم يخضع بعد ذلك لمرحلة الحرق بالحرق.

ويتمثل الغرض من هذه الخطوة في إزالة الرطوبة وتثبيت الهيكل، وتهيئته للتزجيج اللاحق. تم تصميم القالب عالي الدقة لجعل كل عينة متناسقة الشكل وذات سطح أملس.

- التزجيج والحرق في درجات الحرارة العالية

يعتبر التزجيج من بين أهم الخطوات التي تحدد شكل السيراميك ومظهره. جينهوا يوفر مجموعة كبيرة من الطلاءات الزجاجية، بما في ذلك الطلاء الزجاجي شديد اللمعان والطلاء الزجاجي غير اللامع والطلاء الزجاجي المتشقق والطلاء الزجاجي الملون.

خلال مرحلة أخذ عينات السيراميك، يمكن للعميل تقييم سطوع ولمعان وملمس التزجيج من خلال فحص العينات.

بعد ذلك، سنقوم بحرق في درجة حرارة عالية أو منخفضة:

- يزيد الحرق بالحرارة المرتفعة، حوالي 1300 درجة مئوية، من صلابة ومقاومة الحرارة، مما يجعلها مناسبة لصواني الخبز وأدوات المائدة.

- الحرق على درجة حرارة منخفضة عند حوالي 800 درجة مئوية - 1000 درجة مئوية: وهذا يحافظ على الألوان الزاهية والتفاصيل الدقيقة للزخرفة؛ ومن الأمثلة على ذلك جرار الشموع وأطقم الحمامات.

- الطباعة والديكور

بالنسبة لـ منتجات السيراميك المخصصة, ، شعار العلامة التجارية أو النمط الزخرفي هو مفتاح التعرف على العلامة التجارية.

تدعم Jinhua عمليات مختلفة مثل طباعة الشاشة والشارات والرسم اليدوي والختم الساخن. يمكن تعديل الموضع والحجم بمرونة وفقًا لتأثير العينة، مما يضمن عرض العلامة التجارية والجاذبية الجمالية.

- اختبار العينة وتأكيد العميل

بعد اكتمال العينة، يقوم فريق مراقبة الجودة في جينهوا باختبارها من عدة جوانب، بما في ذلك الحجم والوزن واختلاف اللون ومقاومة الحرارة واللمعان.

بعد أن يتأكد العميل من العينة، نحتفظ بعينة قياسية للمقارنة والتحكم أثناء الإنتاج بكميات كبيرة، مما يضمن أن تكون المنتجات المجمعة متوافقة تمامًا مع العينة.

عينة من خصائص العملية للمنتجات المختلفة

- عينات أواني الطعام الخزفية

أواني عشاء سيراميك تركز العينات على اللمعان والسماكة وثبات التراص. سنقوم باختبار مقاومة الخدش ومقاومة الأحماض والقلويات ونعومة السطح للتأكد من أنه يظل كالجديد حتى بعد الاستخدام طويل الأمد.

- عينات أطباق الخبز

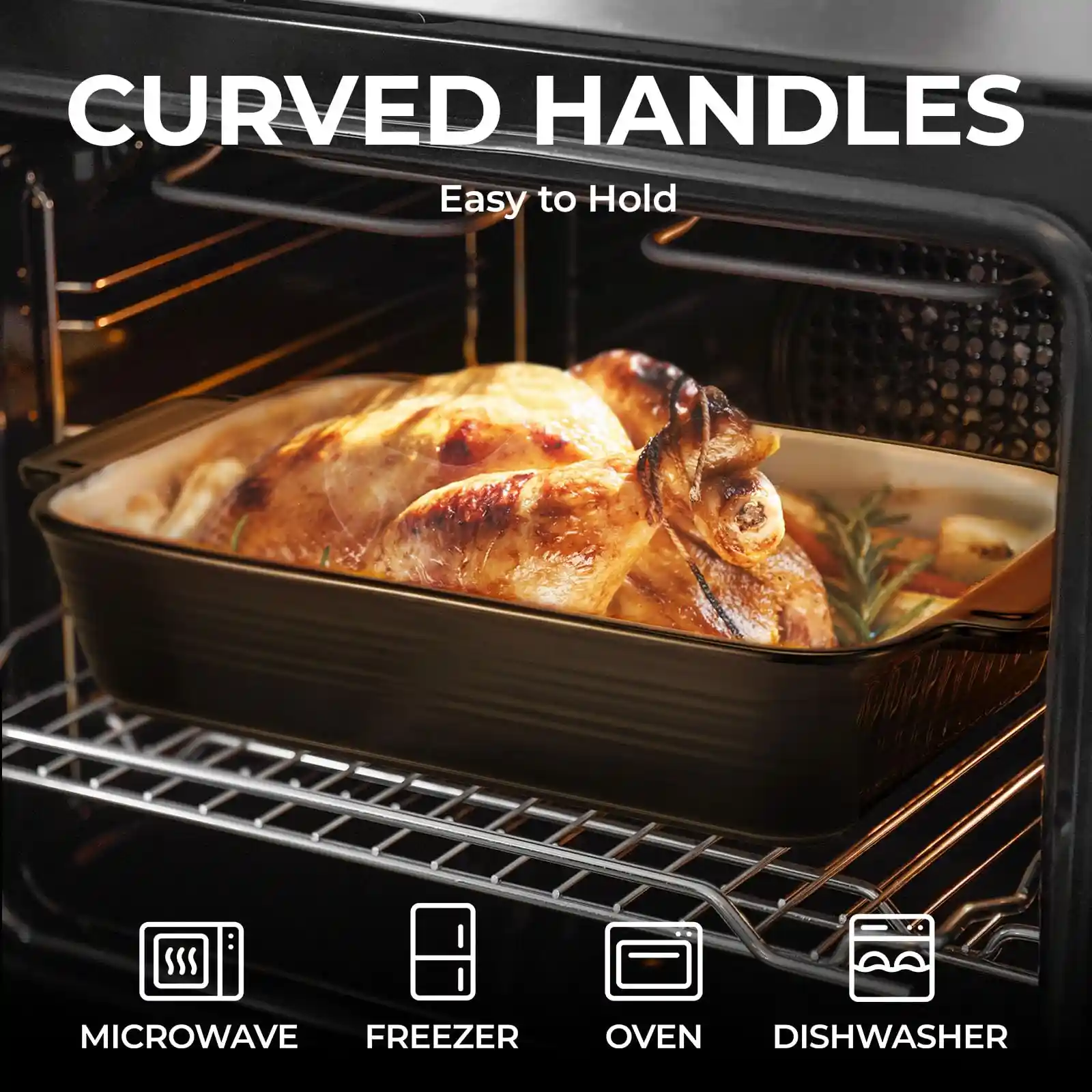

أطباق الخبز يجب أن تجتاز العينات اختبار مقاومة الحرارة العالية لضمان عدم تشققها أو تشوهها في الفرن. ويُعد اختبار مقاومة بقع الزيت للتزجيج خطوة حاسمة لضمان سهولة التنظيف وسلامة الطعام.

- عينات أطقم أطقم الحمام

عينات مجموعة الحمام يجب أن توازن بين مقاومة الماء والجمال. تقدم Jinhua مجموعة متنوعة من التصاميم - من الخزف الأبيض البسيط إلى الطلاء الزجاجي الملون - مما يتيح للعملاء العثور بسهولة على التصميم الذي يتناسب مع أسلوب حمامهم.

- عينات برطمانات الشموع

برطمان شمعة يركز اختبار العينة على مقاومة الحرارة ومنع تسرب الشمع وأداء الختم. يمكن للعملاء تحديد اللون وشكل الغطاء وتأثير عرض الشعار في مرحلة العينة، مما يوفر مرجعًا دقيقًا للإنتاج بكميات كبيرة لاحقًا.

الأسئلة المتداولة حول أخذ عينات السيراميك

- ما هي مدة مهلة العينة؟ بشكل عام من 7 إلى 15 يومًا، ويتم تعديلها حسب درجة التعقيد.

- هل رسوم العينة قابلة للاسترداد؟ معظم المنتجات قابلة للاسترداد بعد تأكيد الطلب.

- هل يمكن تعديل العينة؟ يمكن إجراء التعديلات عدة مرات حتى يتحقق الرضا.

- كيف يتم ضمان الاتساق بين العينات والطلبات بالجملة؟ تحتفظ Jinhua بالعينات الموقعة وتنتج بدقة وفقًا لمعايير العينات.

- هل شحن العينات الدولية آمن؟ نستخدم عبوات واقية متعددة الطبقات لضمان وصول العينات سليمة إلى أيدي عملائنا.

لماذا تختار خدمة أخذ عينات السيراميك من جينهوا؟

بصفتك الشركة المصنعة للسيراميك للاستخدام اليومي مع سنوات عديدة من الخبرة, جينهوا خدمة عملية كاملة من التصميم إلى أخذ العينات إلى الإنتاج بكميات كبيرة.

لا يقتصر دورنا في أخذ عينات السيراميك على الكفاءة فحسب، بل يركز أيضاً على التفاصيل والجودة:

- لدينا فريق تصميم وقوالب محترف لتلبية احتياجات التخصيص المتنوعة.

- نحن ندعم خدمات تصنيع المعدات الأصلية وتصنيع المعدات الأصلية.

- يضمن نظام اختبار العينات الصارم استقرار الجودة.

- يمكننا الاستجابة بسرعة لطلبات العينات من العملاء العالميين، مما يحسن من كفاءة المشروع.

الخاتمة: البدء بالعينات، وابتكار منتجات خزفية مثالية.

كل نجاح مشروع تخصيص السيراميك تبدأ بعينة.

جينهوا نؤمن إيمانًا راسخًا بأن أخذ عينات السيراميك الدقيقة وعالية الجودة هو العنصر الأساسي في بناء ثقة العملاء وضمان اتساق المنتج. سواءً كنت بحاجة إلى أواني خبز متينة ذات درجة حرارة عالية، أو أدوات مائدة سيراميك أنيقة، أو أطقم حمامات رائعة، أو أواني شموع ذات تصميم فريد, تقدم Jinhua حلاً متكاملاً لمنتجات السيراميك المخصصة.

من العينة إلى الإنتاج الضخم، نسعى جاهدين لجعل كل تفاصيل السيراميك أقرب ما يكون إلى الكمال قدر الإمكان.