بسبب جماليته واستدامته البيئية بالإضافة إلى متانته, أواني طعام من السيراميك سرعان ما أصبحت مفضلة لدى المزيد والمزيد من المطاعم والفنادق وشركات السلع المنزلية في سوق أدوات المائدة العالمية. ومع الطلب المتزايد على التخصيص، أصبحت نماذج تصنيع المعدات الأصلية وتصنيع التصميم الشخصي هي الأنماط الرئيسية للتعاون في صناعة السيراميك. بالنسبة لأولئك الذين يفضلون إنشاء علامتهم التجارية الخاصة، فإن معرفة الفرق بين أواني الطعام الخزفية المصنوعة من OEM و ODM هي الخطوة الأولى للعثور على الشركة المصنعة لأواني الطعام الخزفية المناسبة.

الفرق بين تصنيع المعدات الأصلية وتصنيع التصميم الأصلي: بديلان في تطوير علامة تجارية لأدوات المائدة الخزفية

1. أواني طعام سيراميك OEM: تصميمك، علامتك التجارية

نموذج OEM هو النموذج الذي يوفر فيه العميل التصميم والعلامة التجارية ومواصفات المنتج، ويتولى المصنع عملية الإنتاج. يتم اعتماد هذا النموذج على نطاق واسع من قبل العلامات التجارية الراسخة لأنه ينطوي على حرية العلامة التجارية والتوحيد في التصميم.

المزايا:

- تحكم كامل في التصميم والجودة

- يدعم الشعارات والتغليف وأنظمة الألوان الفريدة من نوعها

- مناسبة للعلامات التجارية ذات المكانة الراسخة في السوق

العيوب:

- ارتفاع تكاليف التطوير ودورات الإنتاج الطويلة

- ارتفاع الحد الأدنى لكمية الطلب (MOQ)

أواني الطعام الخزفية المصنوعة من السيراميك من OEM هو خيار مثالي للمشترين الذين يبحثون عن صورة فريدة للعلامة التجارية. فهو يساعد العلامات التجارية في الحفاظ على التمايز في السوق وبناء القدرة التنافسية على المدى الطويل.

2. أواني الطعام الخزفية ODM: طريقة سريعة وفعّالة لدخول السوق

يوفر نموذج ODM (الشركة المصنعة للتصميم الأصلي) للشركة المصنعة تصميمًا أصليًا، ويمكن للعميل اختيار الأنماط الحالية لمبيعات العلامة الخاصة.

المزايا:

- تصميم مثبت، زيادة سريعة في الإنتاج

- تكاليف أقل، مناسبة للعلامات التجارية الصغيرة والمتوسطة الحجم أو العلامات التجارية الناشئة

- خط إنتاج واسع، يمكن اختياره بناءً على اتجاهات السوق

العيوب:

- حصرية التصميم المحدودة

- صعوبة في عرض أسلوب العلامة التجارية الفريد من نوعه

للعلامات التجارية التي تتطلع إلى الإطلاق السريع أو اختبار استجابة السوق, أواني الطعام الخزفية المصنوعة من السيراميك ODM خياراً أكثر مرونة.

المنتجات ذات الصلة

تحليل عملية تصنيع المعدات الأصلية/التصنيع حسب الطلب في تصنيع أواني الطعام الخزفية

سواءً مع مصنعي أواني الطعام المحترفين سواءً مع OEM أو ODM، سيضمن مصنعو أواني الطعام المحترفون جودة المنتج وكفاءة الشحن من خلال عمليات موحدة.

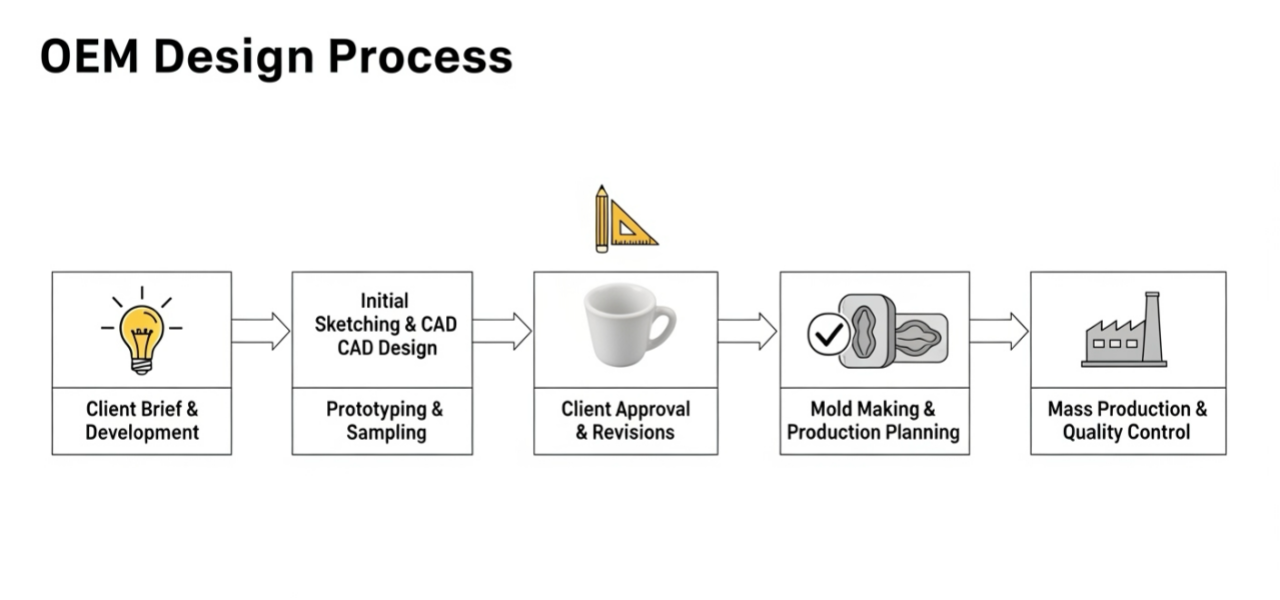

مرحلة التصميم والتأكيد

- صانع المعدات الأصلية: يوفر المشتري رسومات التصميم والمواصفات

- ODM: توفر الشركة المصنعة تصميمًا أصليًا للمشتري للاختيار من بينها

وضع النماذج الأولية والفحص

تنتج الشركة المصنعة عينات بناءً على مخطط التصميم وتفحص اللون والتزجيج والحجم والتأثير الزخرفي.

الإنتاج الضخم

تستخدم عملية الحرق على درجة حرارة عالية (1200 درجة مئوية - 1300 درجة مئوية) لضمان كثافة سيراميك عالية وامتصاص منخفض للماء ومتانة عالية.

فحص الجودة والتعبئة والتغليف

يخضع كل منتج لفحوصات صارمة للجودة والفحوصات البصرية ويدعم طباعة شعار العلامة التجارية والتغليف المخصص.

التوصيل وخدمة ما بعد البيع

ضمان استقرار التوريد والمساعدة في التصدير لضمان سلسلة توريد خالية من القلق للعملاء.

يمكن أن يدمج مصنع أواني الطعام الفاخر بين التصميم والإنتاج والتعبئة والشحن بشكل متناغم لتحقيق التنفيذ الفعال لمشاريع تصنيع المعدات الأصلية وتصنيع التصميم الشخصي.

كيف تقوم شركة جينهوا بفعالية بإنتاج السيراميك على نطاق واسع لتصنيع المعدات الأصلية/التصنيع حسب الطلب؟

بصفتك تصنيع أواني الطعام الاحترافية المؤسسة, جينهوا تمتلك نظام إنتاج عالي المستوى ونظامًا متطورًا لمراقبة الجودة، مما يمكنها من ضمان جودة عالية مع توريد آمن، حتى بالنسبة للكميات الكبيرة.

1. خطوط الإنتاج الذكية والمعدات الذكية

تستخدم جينهوا عمليات التشكيل الآلي، والتزجيج الذكي، وعمليات فرن التحميل الآلي لجعل كفاءة الإنتاج وتوحيد الجودة تتحسن بشكل كبير، مع خضوع جميع سيراميك أدوات المائدة للمعايير الدولية.

2. نظام إدارة الجودة الخاص

هناك رقابة على الجودة في كل عملية بدءًا من شراء المواد الخام إلى الحرق بالنار العالية لإنتاج منتجات خالية من التشققات واختلاف الألوان والشوائب. جينهوا حاصلة على شهادة الأيزو 9001 وتحتوي على شهادات اختبار الامتثال لبلدان التصدير.

3. النماذج الأولية السريعة وخدمات التخصيص

إذا كان تصميم OEM أو ODM مطلوبًا من قبل العملاء، يمكن لـ Jinhua إكمال التحقق من العينة خلال فترة زمنية قصيرة، مما يوفر لهم الوقت اللازم للتسويق.

4. إدارة الطلبات المخصصة والقدرة على التسليم

تقدم Jinhua طلبيات تجريبية لدفعات صغيرة وإنتاج واسع النطاق. ومن خلال الجمع بين ورش العمل الخاصة بها وورش العمل التعاونية، فإننا نضمن التسليم في الوقت المناسب والتوريد المستقر لعملائنا في الخارج.

لماذا تختار جينهوا كشركة مصنعة لأواني الطعام؟

سيراميك جينهوا مصنع أواني الطعام الخبير OEM / ODM

- 20 عامًا من الخبرة في مجال التصنيع الخبير:

تتمتع Jinhua بخبرة في مجال البحث والتطوير والتصميم وبيع أواني الطعام الخزفية بالجملة للتصدير إلى العديد من دول العالم. - مجموعة منتجات واسعة النطاق:

من أواني الخبز إلى أطقم أدوات المائدة، والأطباق الخزفية، والأطباق الخزفية، وأطقم الحمامات، والشمعدانات، التي تلبي مختلف المتطلبات. - قدرات قوية لتصنيع المعدات الأصلية/التصنيع حسب الطلب:

يمكن تخصيص الأنماط والأحجام وألوان التزجيج والتغليف حسب الطلب. - فعالية عالية من حيث التكلفة وخدمة عالية الجودة:

نحافظ على الجودة من خلال تقديم أسعار تنافسية للغاية وخدمات ما بعد البيع السريعة.

جينهوا هي أفضل شريك للعلامات التجارية العالمية التي تبحث عن مصنع أواني طعام موثوق به. يمكنك الاعتماد على Jinhua كمورد للمطاعم، أو علامة تجارية للأثاث المنزلي، أو بائع تجزئة عبر الإنترنت. تقدم Jinhua خدمات احترافية خدمات تصنيع المعدات الأصلية وتصنيع التصميم الأصلي لأواني الطعام الخزفية.

الخلاصة: الشراكة مع جينهوا لخلق قيمة فريدة للعلامة التجارية للسيراميك

يعد اختيار النموذج الصحيح للشراكة أمرًا مهمًا لنجاح العلامة التجارية. يسمح لك تصنيع المعدات الأصلية بالحفاظ على حصرية علامتك التجارية، ويسمح لك تصنيع المعدات الأصلية بالدخول السريع إلى السوق.

بفضل خبرتنا العميقة وتقنيتنا المتقدمة وخدمة العملاء الممتازة, جينهوا توفر للعملاء خدمة تصنيع سيراميك تنافسية وفعالة وعالية الجودة.

سواء كنت ترغب في عقد شراكة طويلة الأجل أو ترغب في تصنيع أواني الطعام الخزفية التي تحمل علامتك التجارية، فإن جينهوا شركة جديرة بالثقة.

اتصل بنا لمزيد من المعلومات عن التخصيص حسب الطلب/التصنيع حسب الطلب. دع علامتك التجارية الخزفية تبدأ مع جينهوا.