Competitiveness in the global supply chain is growing rapidly and many brands, importers, home furnishing retailers and cross border sellers are considering whether their suppliers have international certifications. In particular, the ceramic industry produces goods that come into direct contact with food, the environment and consumers’ daily activities so choosing a certified ceramic manufacturer has become more than just a standard for purchasing, but an essential factor for ensuring the safety and compliance of a brand as well as for planning for future development.

Market demands for product quality, the environment and social responsibility have led to an increase in what businesses view as an integral element of procurement, thus it is a major component when creating a strategic plan. So what sets it apart when businesses partner with a manufacturer who is certified to produce ceramics? How serious is this consideration for maintaining continuity of business?

The following article will provide insight to many perspectives on the benefits of partnering with a Certified Ceramic Manufacturer and introduce Jinhua, a professional manufacturer of daily use ceramics and holder of several international certifications.

What is a Certified Ceramic Manufacturer? Why is Certification So Crucial?

Certified Ceramic Manufacturers are those who have satisfied international certification requirements for quality management systems, environmental management systems, occupational health and safety management systems and social responsibility. The process of certification proves not only that the manufacturer’s production process and management system comply with international standards but also demonstrates the manufacturer’s commitment to producing quality products, protecting the environment and producing in a responsible manner.

Some examples of the most common international certifications are:

- ISO 9001: Quality Management System – Certifying that the manufacturer produces ceramic products consistently in accordance with the required quality standards, as defined by the manufacturer, from the raw material stage through to the finished product.

- ISO 14001: Environmental Management System – Certifying that the manufacturer produces ceramic products in a manner which is environmentally responsible, energy-efficient and sustainable.

- ISO 45001: Occupational Health and Safety Management System – Certifying that the manufacturer is providing a safe workplace for employees, reducing the likelihood of accidents occurring during production.

- BSCI: Social Responsibility Audit – Certifying that the manufacturer meets the social responsibility sourcing standards of the largest European retailers.

The benefits of these certifications are great for Certified Ceramic Manufacturers as they provide them with a more stable production environment, a greater consistency in quality of product produced and the assurance that they are producing products in an environmentally and socially responsible way.

Why is partnering with a Certified Ceramic Manufacturer the safest choice?

1. Stable and Reliable Product Quality

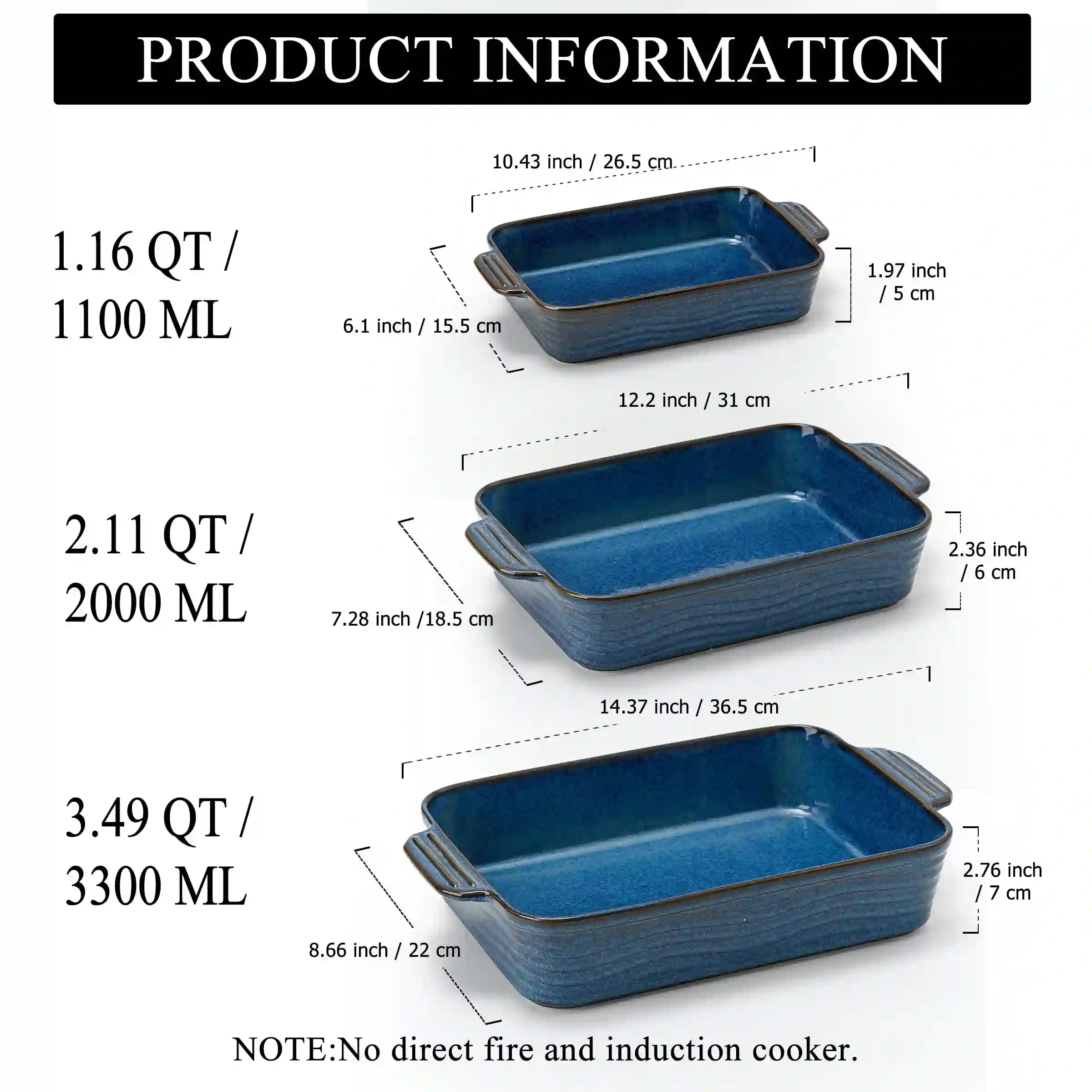

Certified ceramic manufacturers typically have rigorous quality management processes, including:

- Precise control of firing temperature

- Stable glaze ratios

- Testing of finished products for water absorption, thermal shock resistance, and metal migration, etc.

- Multiple quality inspections

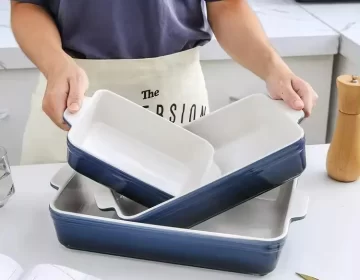

This is especially crucial for everyday ceramic products such as baking trays, tableware sets, ceramic bowls, and ceramic plates, as these products directly relate to food safety. Partnering with a Certified Ceramic Manufacturer can significantly reduce the risk of quality fluctuations, and decrease return and complaint rates.

Traceable Production Process, Compliant with International Regulations

Certified factories offer greater transparency in production management, encompassing:

- Traceable raw material sourcing

- Strict record-keeping for each process

- Factory areas, equipment, and workshops meet audit standards

- All products comply with food contact safety standards (such as EU LFGB and US FDA requirements).

For cross-border e-commerce and importers from Europe and the US, this means:

- Lower compliance risks

- Easier access to large chain retail channels

- Greater compliance with global sustainability requirements

Higher Market Trust and Brand Competitiveness

Brands partnering with Certified Ceramic Manufacturers have greater credibility in their external communications:

- “Food-grade safety guarantee”

- “Green and environmentally friendly production”

- “Compliant with EU and international standards”

Consumers are more willing to trust them, and buyers and distributors are more likely to accept their products, especially in demanding markets like Europe and the US.

More Stable Delivery Times and More Standardized Management

Ceramic manufacturers with ISO management systems have more standardized production arrangements:

- Clear order management system

- Stable delivery times

- Large-scale production is less prone to delays

- Reasonable capacity planning

This is crucial for supermarkets, hotel supply chains, or brand partners requiring large-volume supply.

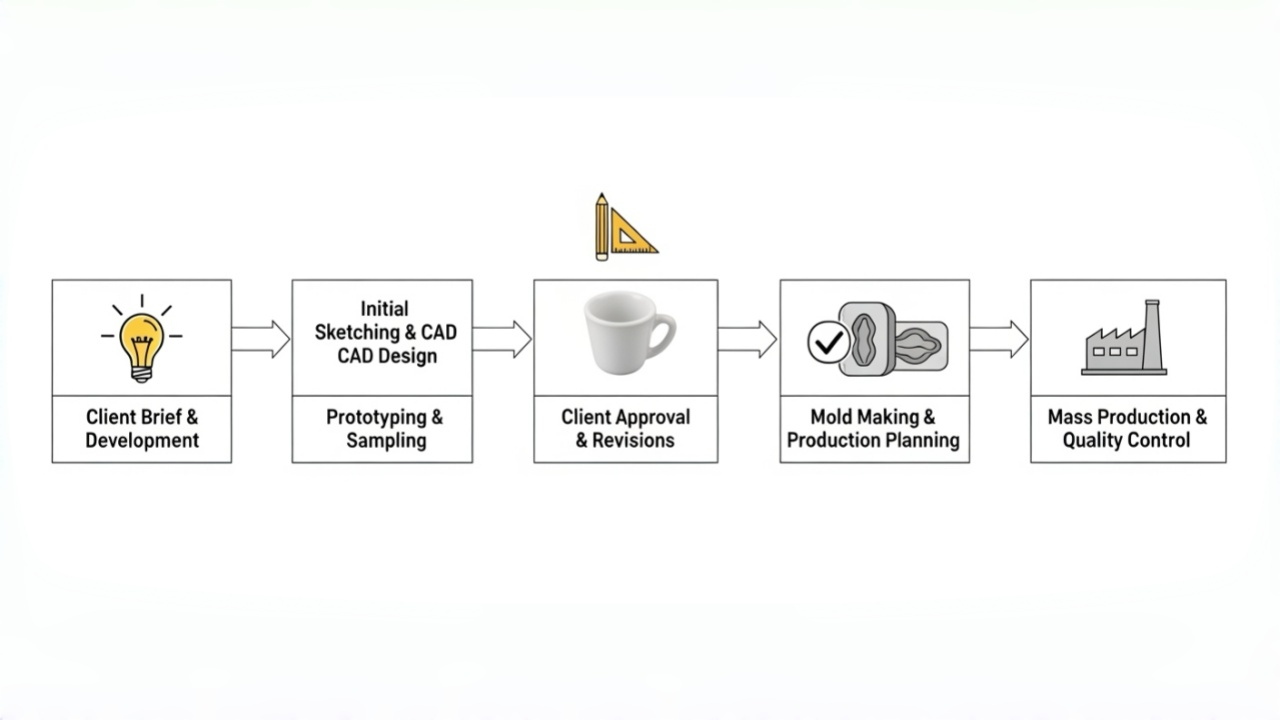

Stronger OEM/ODM Customization Capabilities

Certified Ceramic Manufacturers typically possess more mature design and R&D capabilities, enabling them to provide:

- New mold development

- Professional color and glaze matching

- Product structure design and packaging design

- Rapid sample production

- Stable mass production

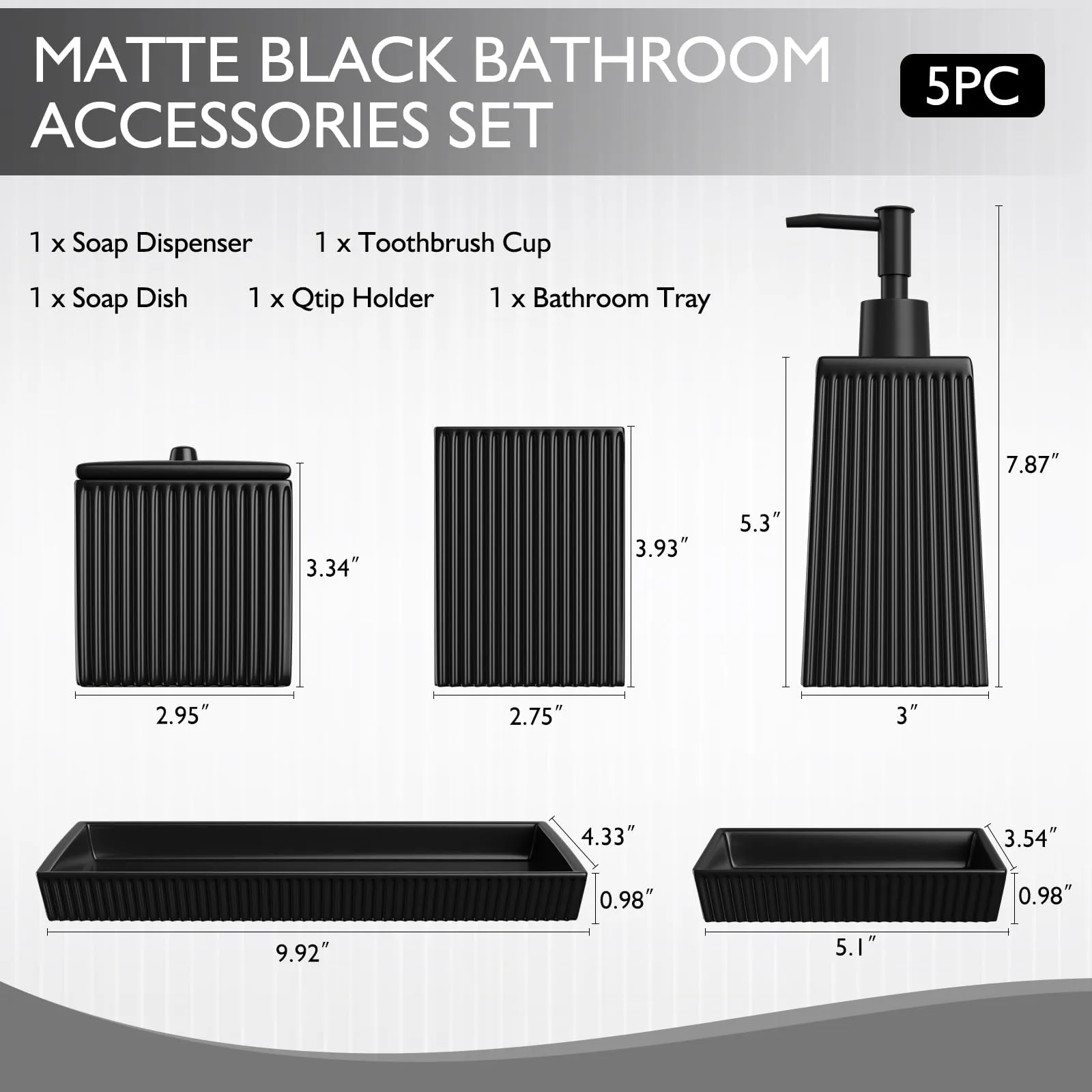

High-quality customization is possible for products such as baking dishes, dinnerware sets, bathroom sets, and candlesticks.

What are the significant advantages of Certified Ceramic Manufacturers compared to non-certified factories?

| Category | Certified Ceramic Manufacturer | Non-Certified Factory |

|---|---|---|

| Product Quality | Stable, reliable, compliant, and safe | Large fluctuations in quality |

| Production Process | Transparent, traceable, and well-managed | Unstandardized, higher risk |

| Regulatory Compliance | Meets ISO / BSCI / food-contact safety standards | Often fails to meet international requirements |

| After-sales Risk | Lower risk | Higher risk |

| Brand Collaboration | Easier to enter major retail supply chains | Many limitations |

| Environmental & Safety Management | Systematic environmental and safety controls | Random and inconsistent |

Clearly, partnering with a certified ceramic manufacturer provides greater assurance for a company in terms of supply chain, quality management, and brand reputation.

Conclusion: Why Choose Jinhua as Your Certified Ceramic Manufacturer?

Jinhua is a professional manufacturer and wholesaler specializing in daily-use ceramics. With years of production experience and international client cooperation experience, it is a trustworthy Certified Ceramic Manufacturer.

Jinhua’s advantages include:

- Multiple international certifications including BSCI, ISO9001, ISO14001, and ISO45001.

- A comprehensive product line: baking trays, tableware sets, ceramic bowls, ceramic plates, bathroom sets, candlesticks, etc.

- Strong OEM and ODM customization capabilities.

- End-to-end quality control, meeting food contact safety standards.

- Professional service, rapid response, and competitive pricing.

- Support for mass production and flexible order models.

Whether you are a brand owner, wholesaler, e-commerce seller, or hotel supplies buyer, Jinhua can provide you with safe, compliant, high-quality, and competitive ceramic products and customization services.