家庭でのパン作り、ヘルシーな料理、西洋料理の人気が世界中で持続する中、オーブンは家庭の厨房や業務用厨房の重要な設備となっている。ラザニア、焼き飯、ローストミート、パン、ケーキなど、高温で焼くため、焼成器具への要求も高くなっている。様々な材料の中で、, セラミックベークウェア は、均一な熱、高級感のある外観と手触りを提供し、安全で環境に優しいことから、小売業者、ブランド・オーナー、最終消費者の間で人気が高まっている。.

しかし、どんなセラミック製ベーキングパンでも熱に耐えられるわけではありません。大手小売業者、スーパーマーケットのバイヤー、ブランド・オーナーにとって、適切なセラミック製ベーキングパンを選択することが勝利につながるのだ。 卸売セラミックベークウェア は、単に製品の品質や消費者体験が優れているというだけでなく、返品率やブランドの評判、ブランド・パートナーシップの全体的な寿命や成功にも影響を与える可能性がある。では、セラミック製ベーキングパンの中で、高温焼成に適しているのはどれだろうか?大量に購入する場合、どのような点に注意すべきなのだろうか?本稿では、素材、製造工程、安全性、実用性といった側面から、高温焼成用ベークウェア選びの要点を分析した。.

セラミック製ベークウェアにおける高温ベーキングの核心要件

高温焼成とは、一般的に220℃以上の温度で焼くことを指し、プロの料理では250℃~300℃に達するものもあります。この点から、セラミックベークウェアは、このような要求を受けた場合、構造的完全性と熱的性能のバランスを取る必要があります。.

第一に、耐熱性と耐熱衝撃性である。高品質なセラミック製ベーキングパンは、高温で焼成してボディーの密度を高める必要があるため、冷たいパンを高温のオーブンに入れたり、熱いパンを冷たいカウンターに接触させても割れることがない。小売市場にとって、耐熱衝撃性が不十分であることは、しばしばアフターセールス・リスクが高くなることを意味する。.

第二は、均一な加熱である。セラミックは金属よりも熱伝導が遅いとはいえ、素材内の熱の伝わり方が均一であるため、高温になった部分から食品が焦げる可能性が低いという利点があります。これが、セラミック製ベークウェアが高級家庭ユーザーやケータリング業界の間で高く評価されている理由だ。.

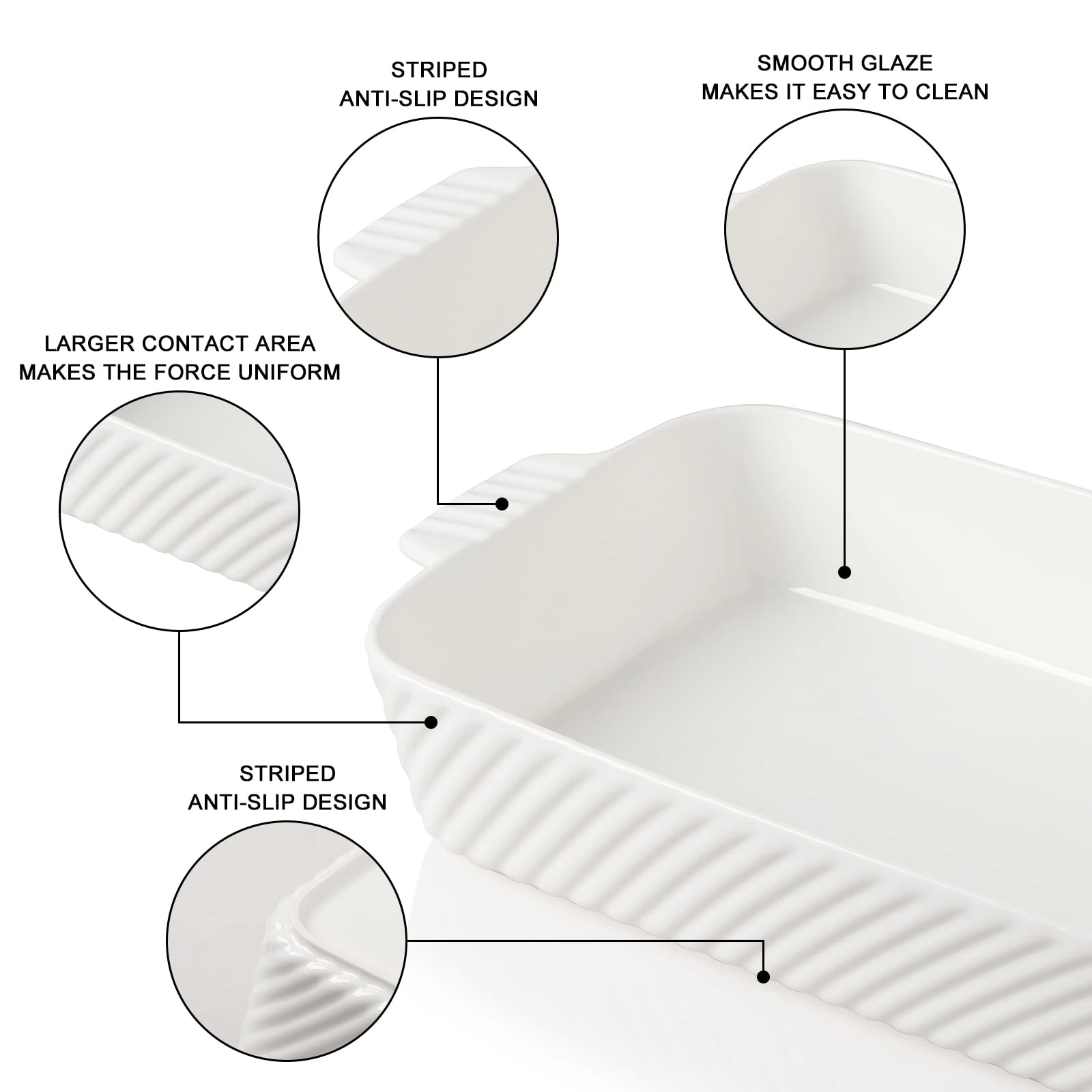

最後に、構造上の厚みとデザインです。高熱焼成用の良質なセラミック製ベーキング・ディッシュは、壁が十分に厚く、高熱調理による変形を防ぐエッジ・デザインが施されています。これは バルク卸売セラミックベークウェア オーダーも同様で、特定のラインの弱点が明らかになるのは、その製品が広範囲に使用された後であることが多い。.

セラミックの種類が高温ベーキングに与える影響

すべての「セラミック」が同じ高温耐性を持っているわけではありません。セラミックの種類による違いを理解することが、正しいセラミック製ベークウェアを選ぶ鍵となります。.

高温セラミックと普通のセラミックの違い

セラミックスの高温焼結は、通常1200℃以上で行われるため、低温セラミックスに比べ、緻密で吸水率が低く、耐熱性、耐クラック性が非常に高いのが特徴です。これらのセラミックスは、高熱で焼成されるベーキングパン、おろし金、缶などに最適で、当社の卸売セラミックベークウェアラインのベストセラーです。.

磁器とセラミックの比較

実際の調達でよくある質問は、“焼き皿は磁器と陶器のどちらが良いのか?”というものだ。答えは絶対ではない。磁器は一般的にきめが細かく、吸水性が低く、高級感があるのに対し、セラミックはデザインの自由度が高く、コスト管理がしやすく、小売市場での大規模なプロモーションに向いている。したがって、スーパーマーケットでは、安定した性能と高い費用対効果からセラミック製ベークウェアを選ぶことが多く、高級ブティック・シリーズでは磁器を使用する部分もあります。.

実用化のすすめ

について 焼き型 長期間の高温に耐える必要がある場合は、耐熱試験に合格した高温焼成の厚い構造のセラミックタイプを選択し、破損率を減らして顧客満足度を向上させることをお勧めします。.

高温焼成プロセス:セラミックベークウェアの品質の鍵

高温のオーブンで焼くためのセラミック製ベークウェアを検討する場合、通常は見た目よりも加工の方が重要です。.

高温焼成の利点

高温焼成はセラミックスの機械的強度を高めるだけでなく、吸水率も高めます。吸水率が低ければ、加熱時にセラミックスが水分の膨張によって割れる危険性が低くなります。これが、プロの卸売セラミックベークウェアサプライヤーが高温窯を使用する基本的な理由です。.

グレーズと高温適合性

釉薬は高温での挙動にも影響する。最良の釉薬は、高温でひび割れたり、変色したり、有害物質を放出したりせず、外観は長期間安定している。小売チャネルにとって、これは数回使用した後も製品の外観が良好であることを意味する。.

工場での一貫性管理

プロセスの一貫性は、大量生産において特に重要です。老舗メーカーは、セラミックベークウェアの各バッチの温度、色、サイズにおいて、標準的な焼成曲線と非常に厳しい品質管理で一貫した結果を提供することができ、バッチごとのリスクを軽減することができます。.

高温ベーキングの安全性:セラミック製品は無害か?

“「セラミック製ベーキングディッシュは無害ですか?”は、小売バイヤーや消費者にとって最も重要な質問の一つです。.

良質のセラミック製ベークウェアは、鉛やカドミウムのような有害な重金属を含まない食品グレードの釉薬で釉薬がかけられており、高温でも有害なものが釉薬から溶け出すことはありません。国や地域によって、食品に接触する材料に関する厳しい要件があるため、これはスーパーマーケット・チャネルや国境を越えた市場にとって特に重要です。.

調達の観点から、健全な認証システムを持つ卸売セラミックベークウェアサプライヤーと提携することで、コンプライアンスのリスクを軽減することができます。ISO9001やISO14001のような体制を満たしている企業は、一般的に、原材料の選択、生産工程の管理、完成品の試験において、より標準化されている。.

さらに、耐高温セラミック素材は洗浄が容易で、高温のために頑固な汚れや化学物質が表面に残ることもなく、全体的な安全性がさらに高まる。.

卸売セラミック製ベーキングウェアを購入する小売スーパーマーケットのための実用的なアドバイス

スーパーマーケットや小売ブランドにとって、適切なものを選ぶことは重要である。 卸売セラミックベークウェア は単に製品を選ぶだけでなく、長期的なパートナーを選ぶことでもある。.

人気のサイズと形状に注目

長方形のベーキングパン、楕円形のベーキングパン、小容量の一人用ベーキングディッシュは、小売チャネルで最も汎用性の高い高温ベーキング製品である。バランスの取れたSKUミックスは、棚の回転率の向上に役立つ。.

パッケージとディスプレイを重視する

高温に適したセラミック製ベークウェアは通常、「すぐに食べられる」外観をしています。小売店向けのカラフルなパッケージと組み合わせることで、販売時点での購入につなげやすくなります。.

カスタマイズと差別化

OEM/ODMによって色、釉薬、セットの組み合わせをカスタマイズすることで、小売業者は均質化した市場において差別化された優位性を確立することができる。の重要な付加価値である。 卸売セラミックベークウェアのパートナーシップ.

結論高温ベーキングに最適なセラミック製ベーキングウェアは?

使用される素材や工程、最終製品の安全性、実用的な用途を考慮すると、高温で焼成され、構造的に安定した食品用釉薬セラミックベークウェアは、高熱でのベーキングに最適な選択肢です。小売や卸売の場合、安定性と予測可能性は、ピーク性能よりも重要であることが多い。.

プロの卸売セラミックベークウェアメーカーを選択すると、製品が高温ベーキングに適用可能であることを保証し、長期的なだけでなく、安定供給の設計をサポートしています。良質のセラミックベーキング皿は、家庭や商業ユーザーのためのトレンドソリューションです。.

金華製陶について

金華セラミックス, 1990年に設立され、研究開発、生産、販売、サービスを行う日常陶磁器メーカーです。陶磁器食器、陶磁器焼皿、陶磁器蝋燭容器、陶磁器浴室セットの生産と卸売を専門とする工場です。.

同社は以下のサービスを提供している。 OEM/ODMカスタマイズサービス, 金華製陶の製品は、小売スーパー、ケータリングブランド、ホームデコレーションチャンネルに深く採用されています。長年にわたり、金華セラミックスは、優れた顧客サービスと競争力のある価格を通じて、卸売セラミックベークウェアのために多くの国際的なクライアントに依存するように発展してきました。.

もしあなたが、頼りになり、安定していて、そして カスタマイズ可能なセラミックベークウェアメーカー, 金華セラミックス は、長い目で見て協力し合う良い選択となるだろう。.